Pipe Anticorrosion Technology

Column:Pipe fitting anticorrosion technology

Time:2020-08-26

Wear and corrosion exist in every field in industrial production. The corrosion resistant materials should be selected on basis of the chemical materials in contact, and comprehensive considerations shall be made to the corrosion resistance and economic efficiency. Proper selection and use of corrosion coatings can provide better protection to the pipe fitting properly applied, and can increase the service lives of equipment and ensure that the equipment operate safely and smoothly.

The corrosion protective coating at the surface of pipes generally falls in two categories, namely coating with metal plating and with non-metal plating (plastic or ceramic coatings).

Metal coating -- chemical nickel-plating technology

1. It has high corrosion resistance and much higher performance than stainless steel in corrosion protection.

2. The coating is compact with low porosity, good cohesion, good abrasive resistance and pleasing surface hardness.

3. It is featured by good thermal resistance, low electrical resistance and good weld ability.

4. The surface is clean and bright.

5. A variety of shapes is supported in plating. There are no restrictions on the profile of the work piece and relatively deep hole and inner cavity can be processed.

6. A large variety of materials are allowed. Coating can be realized on a variety of materials including steel, copper, aluminum, zinc, plastics, nylon, glass, rubber and wood.

Coating on plastics——(PE, F-40, PO)

A great many types of plastics can be coated, including polyethylene, polyolefin composite, Ethylenetetrafluoroethylene (ETFE). It has good performance in thermal resistance, corrosion resistance, strong cohesion, and pleasing mechanical performances and therefore has a good prospect in application in liners, pipelines, pumps and valves.

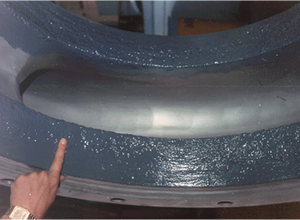

The ceramic coating is a composite material reinforced by ceramic particulates and when applied on metal or non-metal surfaces, it can improve the wear resistance and corrosion performance. It has significant advantages over other wear resisting and corrosion resistance technologies and is easy to use, apply and repair. Under unstable chemical circumstances, it can still maintain prominent chemical resistance and are featured by the strong cohesion, high strength, high density and wide application.

Tel:022-63288515

Tel:022-63288515

Fax:022-63285515

Fax:022-63285515

No.334, Wanxiang Road, Dagang District, Tianjin

No.334, Wanxiang Road, Dagang District, Tianjin